| Model |

: |

DN.NA.01 |

| Material of construction |

: |

MS with powder coated finish |

| Operations |

: |

Digestion, Distillation and Scrubb |

| Cooling System & Automatic |

: |

Through water coil condenser in higher models |

| No of samples |

: |

6 nos |

| Tube dimension |

: |

42 x 300mm |

| Tube capacity |

: |

250ml (Borosilicate Glass 3.3) |

| Process controller |

: |

4.3” TFT touch screen controller |

| Mode of operation |

: |

Auto and Manual |

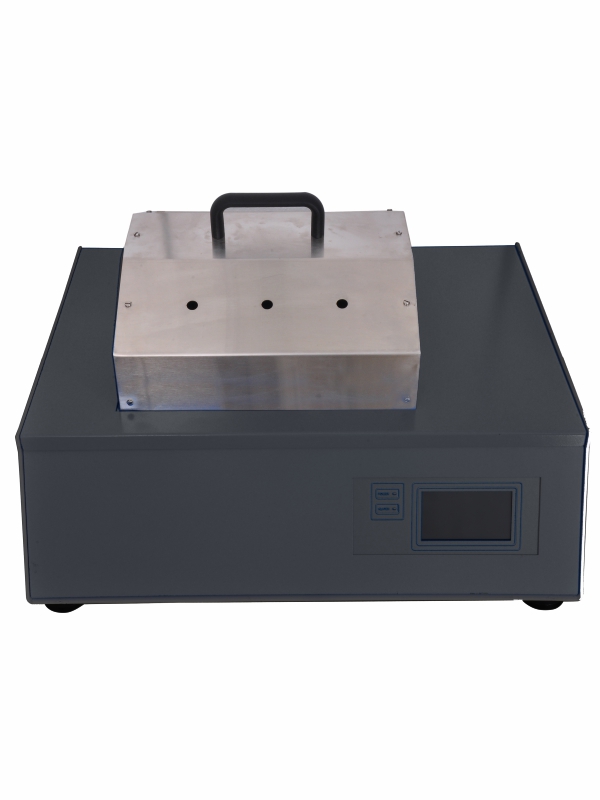

| Digestion Heating block |

: |

Extruded Aluminium block HE 30 Grade 6063 for 6 samples |

| Digestion Heater |

: |

Casted Aluminium alloy heater IS 4159 |

| Digestion Heater wattage |

: |

1500 W |

| Digestion Temperature controller |

: |

PID controller |

| Digestion Temperature Range |

: |

50 degree to 450 degree |

| Digestion temperature accuracy |

: |

+/- 1% |

| Digestion temperature sensor |

: |

Chromal K type thermocouple upto 1200°C |

| Digestion program |

: |

5 program and 5 steps |

| Digestion program parameter |

: |

Temperature and time |

| Digestion block insulation |

: |

Ceramic wool |

| Digestion acid fumes removal |

: |

Teflon adaptor fuse to manifold using & outlet connected to the glass suction pump |

| Handle |

: |

Polyamide |

| Two tier console |

: |

To place Insert rack and Manifold Rack |

| Digestion tube insert Rack |

: |

Stainless steel-SS304 with Glossy Finish |

| Digestion Manifold Rack |

: |

Stainless steel-SS304 with Glossy Finish |

| Digestion Drip Tray |

: |

Stainless steel-SS304 with Glossy Finish |

| Exhaust fume condensation |

: |

In water |

| Scrubber tank |

: |

Stainless Steel 304 |

| Scrubber water leveller |

: |

Float switch |

| Scrubber tank capacity |

: |

10 litre |

| Scrubber suction pump |

: |

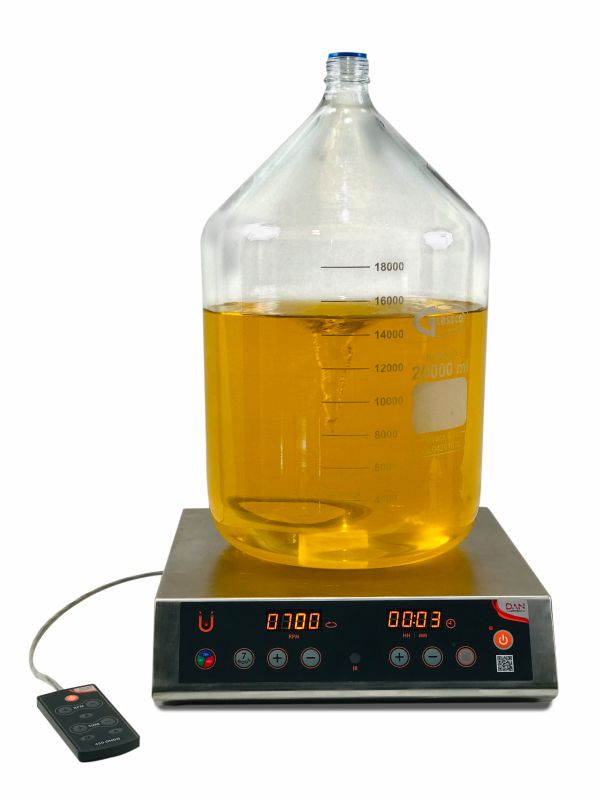

Giant filter pump |

| Distillation expansion vessel |

: |

Glass vessel with Teflon insert for alkali addition inlets nippons for alkali addition and steam addition |

| Scrubber water re-circulation pump |

: |

2 Magnetic pump with flow rate of 18L/min |

| Scrubbing Tubing Hardness |

: |

Silicone tube 70±5 shore A, Temp. resistance -60°C to +200°C |

| Real time monitoring of process |

: |

yes |

| No of distillation |

: |

One at a time |

| Distillation programme |

: |

5 program/3 steps |

| Distillation Programme steps |

: |

Alkali, reaction delay and Process |

| Distillation Dosing pump |

: |

For alkali addition 24 DC Motor 500 ml/min |

| Distillation steam Generator |

: |

Stainless steel-SS304 with pressure release valve to back suction of sample |

| Distillation water condenser |

: |

Glass with 2 bulb and coil condenser |

| Distillation solenoid valves |

: |

For Steam, Refilling and Vent |

| Distillation Heater |

: |

Immersion Heater |

| Distillation Heater Wattage |

: |

1500 W |

| Distilled water tank |

: |

PVC |

| Distilled water tank capacity |

: |

5 Lit |

| Distillation Reagent tank |

: |

PVC |

| Distillation Reagent tank capacity |

: |

2 lit |

| Electrical requirement |

: |

230v/50Hz/16A |

| Unit Dimension |

: |

32 x 26 x 41 inches |

| Connectivity to printer |

: |

Available for higher models |

| Connectivity to USB |

: |

Available for higher models |

| Real Time Monitoring of Process |

: |

Yes |

| Nitrogen recovery |

: |

99.5% |

| Nitrogen reproductiobility |

: |

+/-1% |

| RSD |

: |

<1% |

| LOD |

: |

1-200 mg with >_0.1mg of Nitrogen |

| Total Time process |

: |

2.5 Hours |